Cheese Making

Practical Action

kept in a refrigerator. A part of this ‘master culture’ (between 1 - 3% of the weight of the batch of

milk) is then used each day for a week. The last part is inoculated into pasteurised milk to form a

new master culture. This method can be continued for several months, provided that good hygiene

is practised, but eventually undesirable bacteria will contaminate the culture and it must be

replaced.

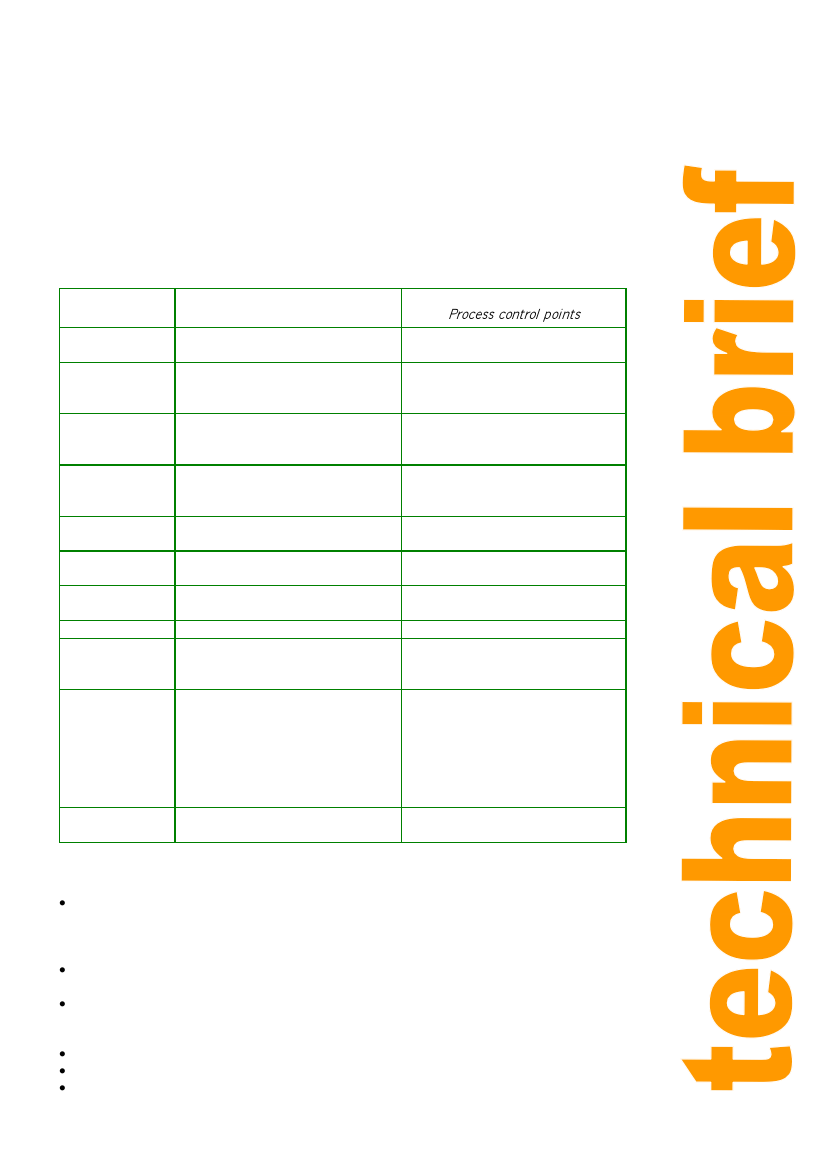

Process control

A process control schedule should be prepared for each product. Table 1 is an example of a

process control schedule for Cheddar cheese production.

Stage in

process

Activity

Process control points

Pasteurise milk Heat to destroy micro-organisms Check temperature and time (e.g.

and enzymes.

75oC +/- 2oC for 1 minute).

Inoculate starter Produce lactic acid

Check amount of starter, activity

of lactic acid bacteria, incubation

time and temperature

Add rennet

Coagulation of milk proteins

Check amount and activity of

rennet, incubation time and

temperature

Heat

Firm the curd

Check time and temperature, rate

of temperature increase (see text

for details)

Cut/drain

Remove whey

Check size of curd pieces, time for

draining

Salting

Add salt

Check amount of salt, degree of

mixing

Press

Remove whey, compress curds

Check time of pressing, amount of

pressure

Pack

In cheesecloth

Check the weight of the cheese

Ripen

Mature the cheese

Check temperature is <15oC, air

humidity is above 80% and time

of storage

Pack/Label

In greaseproof paper or plastic

Check that correct label is used,

film. Attach label or print on the that they are correctly positioned,

wrapper

and show the correct batch

number and use-by or best-before

date (depending on the type of

product - check legislation at the

Bureau of Standards).

Store

Hold at 4-8oC in a refrigerator

Check refrigerator temperature is

6oC +/- 2oC

Table 2: Process control points in Cheddar cheese production

The following control points affect the safety and quality (flavour and texture) of hard cheese:

The temperature and time of heating and cooling the milk. Over-heating and slow cooling

causes changes to flavour, colour and nutritional value; under-heating may result in

inadequate destruction of enzymes and micro-organisms leading to spoilage or food

poisoning.

Correct amount of rennet and starter culture added, which affects the firmness of the

curd.

Incubation temperature to allow rapid production of lactic acid by the inoculated bacteria.

If the temperature is too high the bacteria and rennet will be inactivated, if it is too low

there may be insufficient acid production.

Adequate cutting and draining of the curd to remove most of the whey.

Correct time and temperature of cooking the curd to firm it sufficiently.

Correct amount of salt added.

6